| Call Us View Mobile Number |

Diaphragm Pump

Leading Wholesaler and Trader of 591604 Sempo Aluminum Air Operated Diaphragm Pump, 591611 Sempo Plastic Air Operated Diaphragm Pump, 591612 Sempo Plastic Air Operated Diaphragm Pump, 591613 Sempo Plastic Air Operated Diaphragm Pump, 591614 Sempo Plastic Air Operated Diaphragm Pump, Air Operated Diaphragm Pump – ½″ Aluminium/Neoprene – IMPA 591605, Impa 591601 Air Operated Diaphragm Pump – 1″ (25 Mm, Aluminium/neoprene) |, Impa 591602 Air Operated Diaphragm Pump – 1-1/2″ (40 Mm, Aluminium/neoprene), Mpa 591603 Air Operated Diaphragm Pump – 2″ (50 Mm, Aluminium/neoprene) I, Plastic Diaphragm Wilden Pump, Spare Neoprene Diaphragm, Spare Teflon PTFE Diaphragm and Stainless Steel Air Operated Diaphragm Pump from Mumbai.

| Business Type | Retailer, Trader |

| Brand Name | SEMPO |

| Driven Type | Air Operated |

| Automation Grade | Semi Automatic |

| Application | Industrial |

| Type | Air Operated Diaphragm Pump |

| Country of Origin | India |

| Features | High Performance in Flow Rate, Long Life |

IMPA 591604 Sempo PS15 Air-operated Diaphragm pump, 3-inch aluminium case (Ex. T15, M15, P15) for industrial applications

Air Operated Diaphragm Pump (Aluminium/Neoprene) – Reliable & Low-Maintenance Fluid Handling

The Air Operated Diaphragm Pump (Aluminium/Neoprene) is engineered for simple operation and low-maintenance performance, making it an efficient and dependable solution for general-purpose, non-aggressive fluid handling. Featuring a durable aluminium casing and neoprene internals (diaphragm, balls, and valve seat), this pump ensures smooth operation and long-lasting durability in marine and industrial environments.

Key Features & Benefits:

✅ Aluminium Casing – Lightweight, durable, and corrosion-resistant for extended service life

✅ Neoprene Diaphragm, Balls & Valve Seat – Provides efficient fluid transfer with chemical resistance for non-aggressive liquids

✅ Compressed Air Operated – No electrical components, ensuring spark-free and explosion-proof operation

✅ Low-Maintenance Design – Spare diaphragm available for quick replacement and minimal downtime

✅ Easy Installation & Portable – Compact and lightweight, allowing for hassle-free handling

Technical Specifications:

✔ Pump Size: 3″ (75 mm)

✔ IMPA Code: 591604

Ideal Applications:

✔ General Fluid Transfer – Efficient for water, mild chemicals, and industrial liquid movement

✔ Marine & Shipboard Use – Reliable for onboard fluid pumping and bilge applications

✔ Industrial Processing – Suitable for oil, wastewater, and chemical handling

✔ Hazardous Environments – Safe for spark-free and explosion-proof applications

With its rugged construction and efficient performance, the Air Operated Diaphragm Pump (Aluminium/Neoprene) is a cost-effective, durable, and low-maintenance choice for fluid handling needs in marine and industrial operations.

📩 Contact us today for specifications, bulk orders, or spare parts availability!

| Business Type | Retailer, Trader |

| Brand Name | SEMPO |

| Material | Plastic |

| Driven Type | Air Operated |

| Automation Grade | Semi Automatic |

| Application | Industrial |

| Type | Air Operated Diaphragm Pump |

| Country of Origin | India |

| Features | Long Life, High Performance in Flow Rate |

IMPA 591611 Sempo P-1 Air-operated diaphragm pump with plastic body for lightweight, corrosion-resistant applications"

Air Operated Diaphragm Pump (Plastic) – Chemical-Resistant & Low-Maintenance

The Air Operated Plastic Diaphragm Pump (½″ / 15 mm, IMPA 591611) is designed for high chemical resistance and long-lasting performance, making it ideal for acidic, caustic, and abrasive fluid handling applications. Constructed with a durable polypropylene casing and Teflon (PTFE) diaphragms, balls, and valve seats, this pump ensures superior resistance to harsh chemicals and abrasives, extending its operational lifespan.

Key Features & Benefits:

✅ Polypropylene Casing – Provides lightweight durability and excellent chemical resistance

✅ Teflon (PTFE) Diaphragms, Balls & Valve Seats – Ensures resistance to aggressive chemicals and abrasives

✅ Compressed Air Operated – Spark-free and explosion-proof operation, making it safe for hazardous environments

✅ Long Flex Life – Designed for extended operation and minimal wear

✅ Spare Diaphragm Available – Quick and easy replacement, reducing downtime

✅ Low-Maintenance & Easy to Operate – Compact and lightweight for hassle-free handling

Technical Specifications:

✔ Pump Size: ½″ (15 mm)

✔ IMPA Code: 591611

Ideal Applications:

✔ Acidic & Caustic Fluid Transfer – Suitable for handling strong acids, bases, and aggressive chemicals

✔ Abrasive Applications – Designed to withstand fluids containing particulates

✔ Marine & Industrial Use – Ideal for corrosive fluid pumping in shipboard and industrial settings

✔ Hazardous Environments – Safe for spark-free, explosion-proof operations

Built for chemical resistance, efficiency, and long-term performance, the Air Operated Plastic Diaphragm Pump is an ideal solution for demanding fluid transfer applications.

📩 Contact us today for specifications, bulk orders, or spare parts availability!

| Business Type | Retailer, Trader |

| Brand Name | SEMPO |

| Driven Type | Air Operated |

| Automation Grade | Semi Automatic |

| Application | Industrial |

| Type | Air Operated Diaphragm Pump |

| Country of Origin | India |

| Features | Long Life, High Performance in Flow Rate |

Air Operated Diaphragm Pump (Plastic) – High-Performance Chemical Transfer Solution

The Air Operated Plastic Diaphragm Pump (1″ / 25 mm, IMPA 591612) is engineered for superior chemical resistance, durability, and efficiency, making it ideal for handling aggressive chemicals, acidic/caustic liquids, and abrasive fluids. Built with a polypropylene casing and Teflon (PTFE) diaphragms, balls, and valve seats, this pump offers exceptional resistance to chemical corrosion, abrasion, and temperature variations, ensuring a long flex life and reliable performance.

Key Features & Benefits:

✅ Polypropylene Casing – Lightweight, chemically resistant, and durable

✅ Teflon (PTFE) Diaphragm, Balls & Valve Seats – Ensures maximum resistance to aggressive fluids and high temperatures

✅ Compressed Air Operated – No electricity required, providing spark-free, explosion-proof operation

✅ Abrasive & Corrosive Fluid Compatibility – Handles acidic, caustic, and particle-laden liquids with ease

✅ Long Flex Life – Designed for extended diaphragm durability and minimal maintenance

✅ Spare Diaphragm Available – Ensures quick replacement and reduced downtime

✅ Compact & Easy to Install – Lightweight and efficient, making it simple to operate and maintain

Technical Specifications:

✔ Pump Size: 1″ (25 mm)

✔ IMPA Code: 591612

Ideal Applications:

✔ Chemical & Acidic Liquid Transfer – Safe handling of highly corrosive and reactive chemicals

✔ Abrasive Fluid Pumping – Effective for particle-laden and slurry-like liquids

✔ Marine & Industrial Processing – Reliable in shipboard, wastewater, and chemical industries

✔ Hazardous & Explosion-Prone Environments – Safe for spark-free applications in flammable areas

Designed for exceptional chemical compatibility, durability, and efficiency, the Air Operated Plastic Diaphragm Pump (1″ / 25 mm) is a cost-effective and long-lasting choice for industrial and marine fluid handling needs.

📩 Contact us today for specifications, bulk orders, or spare parts availability!

| Business Type | Supplier, Trader |

| Brand Name | SEMPO |

| Driven Type | Air Operated |

| Automation Grade | Semi Automatic |

| Application | Industrial |

| Type | Air Operated Diaphragm Pump |

| Country of Origin | India |

| Features | Long Life, High Performance in Flow Rate |

IMPA 591613 Sempo P‑4 air‑operated diaphragm pump with plastic body for lightweight, corrosion‑resistant industrial applications.

Air Operated Diaphragm Pump (Plastic) – Superior Chemical & Abrasion Resistance

The Air Operated Plastic Diaphragm Pump (1-1/2″ / 40 mm, IMPA 591613) is specifically designed for handling aggressive chemicals, acidic/caustic liquids, and abrasive fluids. Built with a polypropylene casing and PTFE (Teflon) diaphragms, balls, and valve seats, this pump provides exceptional resistance to chemical corrosion, abrasion, and high temperatures, ensuring long-lasting performance and reliability.

Key Features & Benefits:

✅ Polypropylene Casing – Lightweight, corrosion-resistant, and durable

✅ PTFE (Teflon) Diaphragm, Balls & Valve Seats – Ensures maximum resistance to aggressive fluids and high temperatures

✅ Compressed Air Operated – No electricity required, ensuring spark-free and explosion-proof operation

✅ Ideal for Abrasive & Corrosive Fluids – Handles acidic, caustic, and particle-laden liquids

✅ Long Flex Life – Designed for extended diaphragm durability and minimal wear

✅ Spare Diaphragm Available – Allows for quick replacement and minimal downtime

✅ Compact & Lightweight Design – Easy to install, operate, and maintain

Technical Specifications:

✔ Pump Size: 1-1/2″ (40 mm)

✔ IMPA Code: 591613

Ideal Applications:

✔ Chemical & Acidic Liquid Transfer – Safe handling of highly corrosive and reactive chemicals

✔ Abrasive Fluid Pumping – Effective for particle-laden and slurry-like liquids

✔ Marine & Industrial Processing – Reliable for shipboard, wastewater, and chemical industries

✔ Hazardous & Explosion-Prone Environments – Safe for spark-free operations in flammable areas

Built for exceptional chemical compatibility, efficiency, and durability, the Air Operated Plastic Diaphragm Pump (1-1/2″ / 40 mm) is a cost-effective and long-lasting solution for marine and industrial fluid handling applications.

📩 Contact us today for specifications, bulk orders, or spare parts availability!

| Business Type | Supplier, Trader |

| Brand Name | SEMPO |

| Material | Plastic |

| Driven Type | Air Operated |

| Automation Grade | Semi Automatic |

| Application | Industrial |

| Type | Air Operated Diaphragm Pump |

| Country of Origin | India |

IMPA 591614 Sempo P 8 air operated diaphragm pump with plastic body for lightweight, corrosion resistant industrial applications

Air Operated Diaphragm Pump (Plastic) – High-Performance Chemical & Abrasion Resistance

The Air Operated Plastic Diaphragm Pump (2″ / 50 mm, IMPA 591614) is a durable and efficient pump designed for handling aggressive chemicals, acidic/caustic liquids, and abrasive fluids. Constructed with a polypropylene casing and Teflon (PTFE) diaphragms, balls, and valve seats, this pump provides exceptional chemical resistance, abrasion resistance, and long-term reliability in marine and industrial applications.

Key Features & Benefits:

✅ Polypropylene Casing – Lightweight, corrosion-resistant, and durable

✅ PTFE (Teflon) Diaphragm, Balls & Valve Seats – Ensures maximum resistance to aggressive fluids and high temperatures

✅ Compressed Air Operated – No electricity required, ensuring spark-free and explosion-proof operation

✅ Abrasive & Corrosive Fluid Compatibility – Handles acidic, caustic, and particle-laden liquids

✅ Long Flex Life – Engineered for extended diaphragm durability and minimal wear

✅ Spare Diaphragm Available – Allows for quick replacement and minimal downtime

✅ Compact & Lightweight Design – Easy to install, operate, and maintain

Technical Specifications:

✔ Pump Size: 2″ (50 mm)

✔ IMPA Code: 591614

Ideal Applications:

✔ Chemical & Acidic Liquid Transfer – Suitable for highly corrosive and reactive chemicals

✔ Abrasive Fluid Pumping – Efficient for particle-laden and slurry-like liquids

✔ Marine & Industrial Processing – Reliable for shipboard, wastewater, and chemical industries

✔ Hazardous & Explosion-Prone Environments – Safe for spark-free operations in flammable areas

With its rugged construction, superior chemical compatibility, and efficient performance, the Air Operated Plastic Diaphragm Pump (2″ / 50 mm) is a cost-effective and long-lasting solution for industrial and marine fluid handling needs.

📩 Contact us today for specifications, bulk orders, or spare parts availability!

| Business Type | Supplier, Retailer, Trader, Distributor, Importer |

| Material | Aluminium,Aluminium Casing / Neoprene Internals |

| Country of Origin | India |

| Pneumatic Diaphragm Pump ½″ Alum/Neoprene | IMPA CODE-591605 |

| Pump Size | ½″ (15 mm) |

| Operation | Pneumatic (Air-Operated) |

| Diaphragm Type | Neoprene |

| Valve Seat & Balls | Neoprene |

| Chemical Resistance | Suitable for mild chemicals |

| Installation | Compact, portable, easy to mount |

-

💨 Air-Operated Design – No electrical components; safe for flammable zones

-

⚙️ Aluminium Body – Lightweight, corrosion-resistant, and durable

-

🧪 Neoprene Internals – Smooth operation with resistance to non-aggressive fluids

-

🧰 Low Maintenance – Simple design allows for quick diaphragm replacement

-

📦 Spare Diaphragm Available – Minimizes downtime and extends service life

-

🛠️ General Fluid Transfer – Water, light oils, coolants, and mild chemicals

-

⚓ Marine & Shipboard Use – Bilge, tank, and utility fluid movement

-

🧪 Industrial Processing – Safe for non-corrosive chemical handling

-

🔥 Hazardous Environments – Spark-free operation in explosive zones

-

Marine Engineering & Ship Maintenance

-

Industrial Utility Systems

-

Chemical Handling & Transfer Stations

-

Refueling, Cleaning, and Wastewater Systems

| Business Type | Supplier, Retailer, Trader, Distributor, Importer |

| Application | Industrial |

| Phase | Single Phase |

| Features | Long Life, High Performance in Flow Rate |

| IMPA | 591601 |

| Body Material | Aluminium (lightweight, corrosion-resistant) |

| Internal Components | Neoprene (diaphragm, balls, valve seat) |

| Operation | Compressed Air Driven (pneumatic) |

| Maximum Flow Rate | 100 Liters per Minute |

| Maximum Suction Lift | 4–5 m (dry), 7–8 m (wet) |

✅ Key Features & Benefits

-

💨 Compressed Air Operated – No electricity required; ideal for explosion-proof environments

-

⚙️ Lightweight & Durable Aluminium Casing – Corrosion-resistant and easy to handle

-

🧪 Neoprene Internals – Provides smooth fluid transfer with chemical resistance

-

🔧 Low Maintenance – Simple design facilitates quick diaphragm replacement

-

📦 Cost-Effective & Reliable – Optimized for general-purpose fluid transfer in marine and industrial settings

🚢 Ideal Applications

-

General Fluid Transfer – Suitable for water, mild chemicals, and oils

-

Marine & Shipboard Use – Reliable for onboard fluid movement and bilge pumping

-

Industrial Processing – Ideal for handling mild chemicals and waste fluids

-

Hazardous Environments – Safe for spark-free operations in explosion-prone areas

| Business Type | Exporter, Retailer, Trader, Distributor, Importer |

| Application | Industrial |

| Pump Size | 1-1/2″ (40 mm) |

| IMPA Code | 591602 |

| Body Material | Aluminium (lightweight, corrosion-resistant) |

| Internal Components | Neoprene (diaphragm, balls, valve seat) |

| Operation | Compressed Air Driven (pneumatic) |

| Maximum Flow Rate | 250 Liters per Minute |

| Maximum Suction Lift | 4–5 m (dry), 7–8 m (wet) |

IMPA 591602 Sempo DP40 Diaphragm pump Pneumatic, 1.5-inch aluminium/buna‑N, oil resistant for industrial fluid control

Air Operated Diaphragm Pump (Aluminium/Neoprene) – Durable & Low-Maintenance Fluid Transfer

The Air Operated Diaphragm Pump (Aluminium/Neoprene) is designed for simple operation and low-maintenance service, making it an efficient and reliable choice for fluid transfer applications. With its lightweight yet durable aluminium casing and neoprene internal components (diaphragm, balls, and valve seat), this pump is ideal for general-purpose, non-aggressive liquids.

Key Features & Benefits:

✅ Aluminium Casing – Ensures durability and corrosion resistance

✅ Neoprene Diaphragm, Balls & Valve Seat – Suitable for mild chemical and non-aggressive fluid transfer

✅ Compressed Air Operated – Spark-free and explosion-proof operation, ideal for hazardous environments

✅ Spare Diaphragm Available – Allows for quick and easy maintenance, reducing downtime

✅ Lightweight & Compact Design – Ensures easy handling and installation

Technical Specifications:

✔ Pump Size: 1-1/2″ (40 mm)

✔ IMPA Code: 591602

Ideal Applications:

✔ General Fluid Transfer – Suitable for water, mild chemicals, and industrial liquids

✔ Marine & Shipboard Use – Efficient for onboard fluid movement

✔ Industrial Processing – Ideal for chemical, oil, and waste fluid handling

✔ Hazardous Environments – Safe for spark-free operations in explosion-prone areas

Designed for efficiency, safety, and longevity, the Air Operated Diaphragm Pump (Aluminium/Neoprene) is a cost-effective and low-maintenance solution for marine and industrial fluid handling applications.

📩 Contact us today for specifications, bulk orders, or spare parts availability!

| Business Type | Retailer, Trader |

| Application | Industrial |

| IMPA | 591603 |

| Pump Size | 2″ (50 mm) |

| Material | Aluminium (lightweight, corrosion-resistant) |

| Internal Components | Neoprene (diaphragm, balls, valve seat) |

| Operation | Compressed Air Driven (pneumatic) |

| Maximum Flow Rate | 400 Liters per Minute |

| Maximum Suction Lift | 4–5 m (dry), 7–8 m (wet) |

IMPA 591603 Sempo P8 air-operated Diaphragm pump, 2-inch, aluminium case (Ex. T8, M8) for industrial applications

Air Operated Diaphragm Pump (Aluminium/Neoprene) – Efficient & Low-Maintenance Fluid Transfer

The Air Operated Diaphragm Pump (Aluminium/Neoprene) is designed for easy operation and straightforward maintenance, making it an ideal choice for general-purpose fluid transfer applications. Constructed with a durable aluminium casing and neoprene internal components (diaphragm, balls, and valve seat), this pump ensures reliable performance and long-lasting durability.

Key Features & Benefits:

✅ Aluminium Casing – Lightweight, strong, and corrosion-resistant for marine and industrial applications

✅ Neoprene Diaphragm, Balls & Valve Seat – Provides smooth operation and chemical resistance for non-aggressive fluids

✅ Compressed Air Operated – No electricity required, ensuring spark-free and explosion-proof operation

✅ Spare Diaphragm Available – Quick and easy part replacement to minimize downtime

✅ Compact & Portable Design – Simple installation and maintenance for hassle-free use

Technical Specifications:

✔ Pump Size: 2″ (50 mm)

✔ IMPA Code: 591603

Ideal Applications:

✔ General Fluid Transfer – Suitable for water, mild chemicals, and industrial liquids

✔ Marine & Shipboard Use – Effective for onboard fluid movement and bilge pumping

✔ Industrial Processing – Handles oil, wastewater, and chemical transfer

✔ Hazardous Environments – Safe for spark-free and explosion-proof applications

Designed for durability, safety, and efficiency, the Air Operated Diaphragm Pump (Aluminium/Neoprene) is a cost-effective and reliable solution for marine and industrial fluid handling needs.

📩 Contact us today for specifications, bulk orders, or spare parts availability!

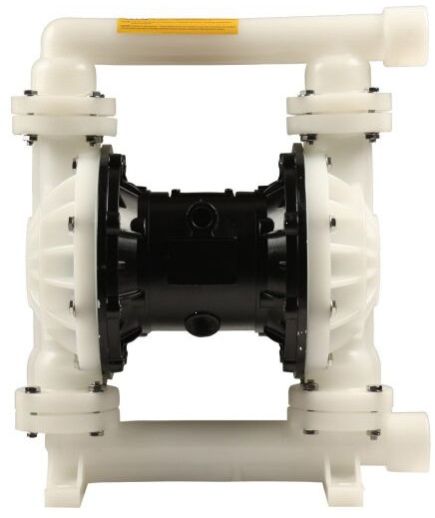

| Business Type | Supplier, Trader |

| Driven Type | Electric |

| Color | White |

| Application | Industrial |

| Pressure | 0-10Bar |

| Country of Origin | India |

| Size Available | ½”, 1”, 1-1/2”, 2” |

| Packaging Type | Box |

| Material | Plastic |

| Feature | Durability, Chemical Resistance, Abrasion Resistance |

Plastic pump lines provide the durability, chemical resistance, abrasion resistance, and temperature range required for a variety of process and waste applications. The standard material combination is composed of polypropylene casing and Teflon diaphragm balls and valve seat.

PTFE diaphragms are extremely suitable for aggressive chemicals. Excellent in acidic & caustic applications with long flex life and handles abrasives well.

Available in: ½”, 1”, 1-1/2”, 2”

| Business Type | Retailer, Trader |

| Material | Casting Steel |

| Finishing | Paint Coated |

| Shape | Round |

| Color | Black |

| Application | Industrial Use |

| Country of Origin | India |

Spare Neoprene Diaphragm – Reliable Replacement for Air-Operated Diaphragm Pumps

We offer high-quality spare neoprene diaphragms for air-operated diaphragm pumps, designed to provide seamless replacement and long-lasting performance. These diaphragms ensure continued efficiency and minimal downtime, making them essential for pump maintenance and reliability.

Available Sizes:

✔ 1″ (25 mm)

✔ 1.5″ (40 mm)

✔ 2″ (50 mm)

Key Features & Benefits:

✅ Durable Neoprene Construction – Offers excellent flexibility, chemical resistance, and longevity

✅ Compatible with Air-Operated Diaphragm Pumps – Ensures optimal performance and seamless fit

✅ Cost-Effective Maintenance Solution – Reduces downtime and replacement costs

✅ Abrasion & Chemical Resistance – Suitable for non-aggressive fluid handling applications

✅ Easy Installation – Designed for quick and hassle-free replacement

Ideal Applications:

✔ Industrial & Marine Pump Maintenance

✔ General Fluid Transfer Systems

✔ Chemical, Water, and Oil Handling Applications

Keep your air-operated diaphragm pumps running smoothly with our reliable spare neoprene diaphragms.

📩 Contact us today for bulk orders, specifications, or compatibility inquiries!

| Business Type | Retailer, Trader |

| Material | PTFE Plastic |

| Shape | Round |

| Color | White |

| Pattern | Plain |

| Type | Ptfe Diaphragm |

| Country of Origin | India |

Spare Teflon (PTFE) Diaphragm – High-Performance Replacement for Air-Operated Diaphragm Pumps

We offer premium Teflon (PTFE) spare diaphragms designed for 1″ (25 mm), 1.5″ (40 mm), and 2″ (50 mm) air-operated diaphragm pumps. These versatile replacement diaphragms are compatible with both plastic and stainless-steel pump models, ensuring broad chemical resistance, durability, and extended service life.

Available Sizes:

✔ 1″ (25 mm)

✔ 1.5″ (40 mm)

✔ 2″ (50 mm)

Key Features & Benefits:

✅ High-Quality PTFE (Teflon) Construction – Superior resistance to aggressive chemicals, high temperatures, and abrasion

✅ Compatible with Both Plastic & Stainless-Steel Pumps – Ensures versatility and wide usage

✅ Extended Service Life – Built for long-lasting durability and reduced wear

✅ Broad Chemical Compatibility – Suitable for acidic, caustic, and abrasive fluid applications

✅ Easy Installation – Quick replacement process to minimize downtime

Ideal Applications:

✔ Chemical Processing & Industrial Fluid Transfer

✔ Pharmaceutical & Food-Grade Applications

✔ Marine & Offshore Pump Systems

✔ Corrosive & High-Temperature Environments

Ensure seamless operation and reliability of your air-operated diaphragm pumps with our durable Teflon (PTFE) spare diaphragms.

📩 Contact us today for bulk orders, specifications, or compatibility inquiries!

| Business Type | Supplier, Trader |

| Country of Origin | India |

| Material | Stainless Steel |

| Application | Industrial |

| Color | Blue |

| Driven Type | Pneumatic |

| Packaging Type | Box |

| Size Available | 1”, 1-1/2”, 2” |

Stainless Steel Diaphragm pump can be used in a variety of applications in sterile processes.

Diaphragm Pump is built with the highest quality precision parts. Long lasting even when used with abrasive fluids, making this product very cost effective. Professionals turn to this pump because it offers an easy, hands-off solution to your fluid handling needs.

Available in: 1”, 1-1/2”, 2”